| You

do have to drill yourself another hole to

mount the shock absorber in the correct

place on the wishbone. As I recall

I have repeated the pitch of the original

holes and extended it by just one pitch.

I have drilled it at 3mm diameter. You then

have to back spot-face the inner face so

that the ball joint on the end of the

shock absorber has something to sit on.

I have also put a spacer between the ball

joint and the wishbone. My spacers

are 2 to 3mm thick but this depends on

how deep you go with the spot face. If

you are careful you may get away with a

washer.

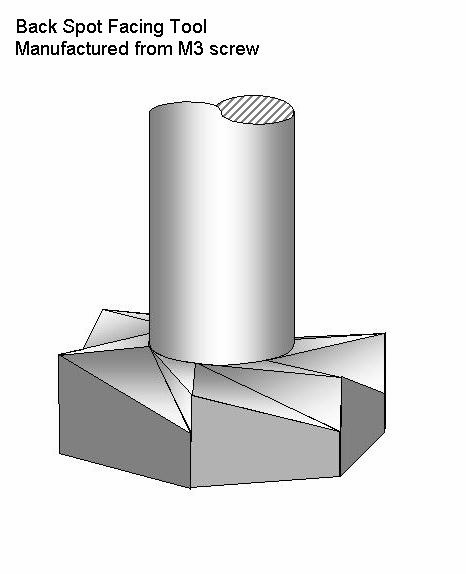

The

spot facing can be done by cutting some

teeth on the back of an M3 screw head as

shown in the picture below.

If you pass the screw through from inside

to out and then place the threaded part

in the jaws of a drill you should be able

to generate the necessary flat face by

rotating the drill and pulling the head

back against the wishbone. Obviously the

screw cannot be too long or you can't get

it in.

You

will have to cut/file some relief for the

head of the ball joint and its as well if

you do this before the spot facing

because it provides relief for the head

of the cutter.

|